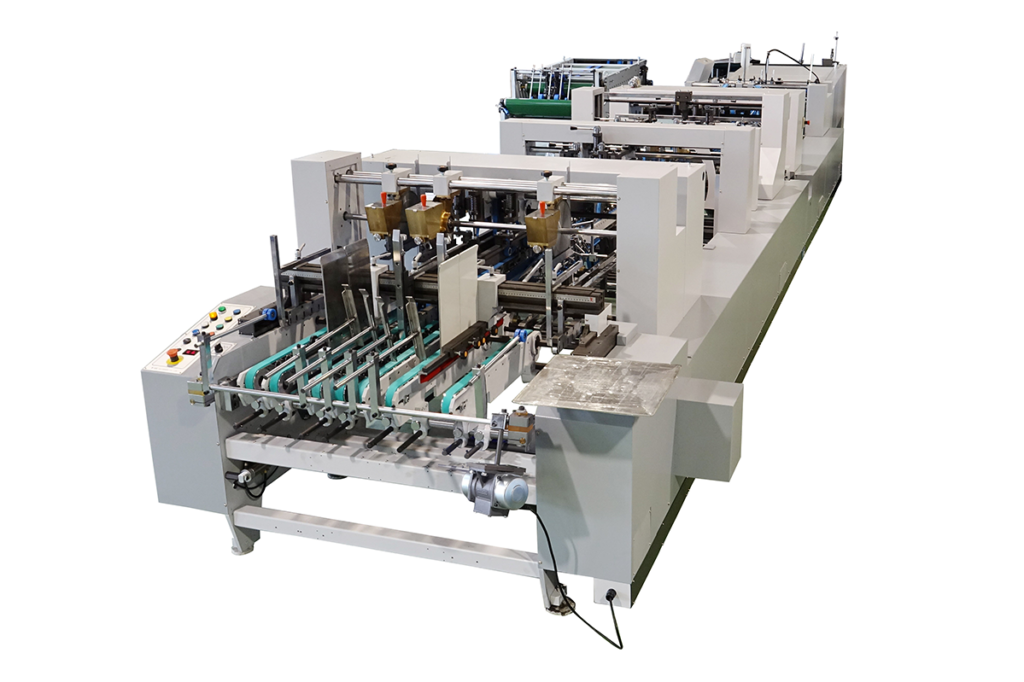

TE-1000WV

High-Speed Folding and Gluing Machine

| Stock Type | Cardboard, E-flute corrugated and decorated board |

| Folding Capability | Straight line, double wall, bottom-folding, 4/6 corners |

| Machine Speed | MAX. 300m/min. |

| Max. Blank width | 1000mm |

| Pre-folding | No. 1 creasing line 180° No. 3 creasing line 135° |

| Feeding | Automatic and continuous feeding |

| Glue Type | Solute |

| Power Required | 15Kw |

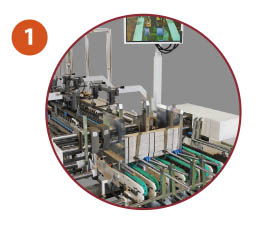

1. Equipped with wireless remote control for easy operation and high mobility.

2. Large full color stacking monitor / CCD system and touch screen setting monitor.

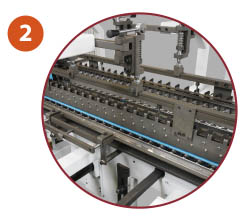

3. Individually adjustable feeding belts without suction. (Suction device is optional)

4. Pneumatic lifter on feeder and pattern feeding mechanism can easily adjust for different sheets width.

5. Position indicator on all carriers to ensure easy and quick change carrier position.

6. Pattern aluminum pressing board with fixing clips make job changing quicker and easier.

7. Pre-fold left/right upper carrier and final fold left/middle/right upper carrier can adjust independently.

8. PLC program control system with two servo motor backing fold system, suitable for 4 &6 point boxes, cake, gift, lock bottom boxes, double wall boxes and standard straight line boxes production, Modulize options can be adapted to run each different appliance easily.

9. Heavy duty inverter for main motor and timing belt for driving motor.

10. Max. machine speed of 300m/min, high efficiency, low noise, durable and easy to maintain.

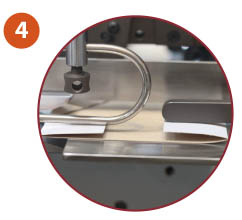

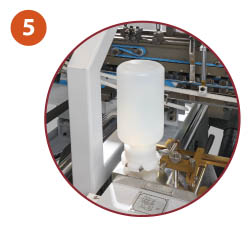

11. Standard lower glue pot unit on both sides, easy to remove, fix and clean.

12. Adjustable pressing roller after final fold section to reach different flatness requirements.

13. Standard machine include independent electrical cabinet, touch screen monitor setting system, volume setting and kicker device.

14. Unique conveyor design help smoother paper stacking and high efficiency.

※ For general reference; customer’s specific designs are welcomed.

FEEDER

ALIGNMENT (OPTION)

PRE-FOLDING

BOTTOM FOLDING

LOWER GLUING

FINAL FOLDING

PRESS FOLDING