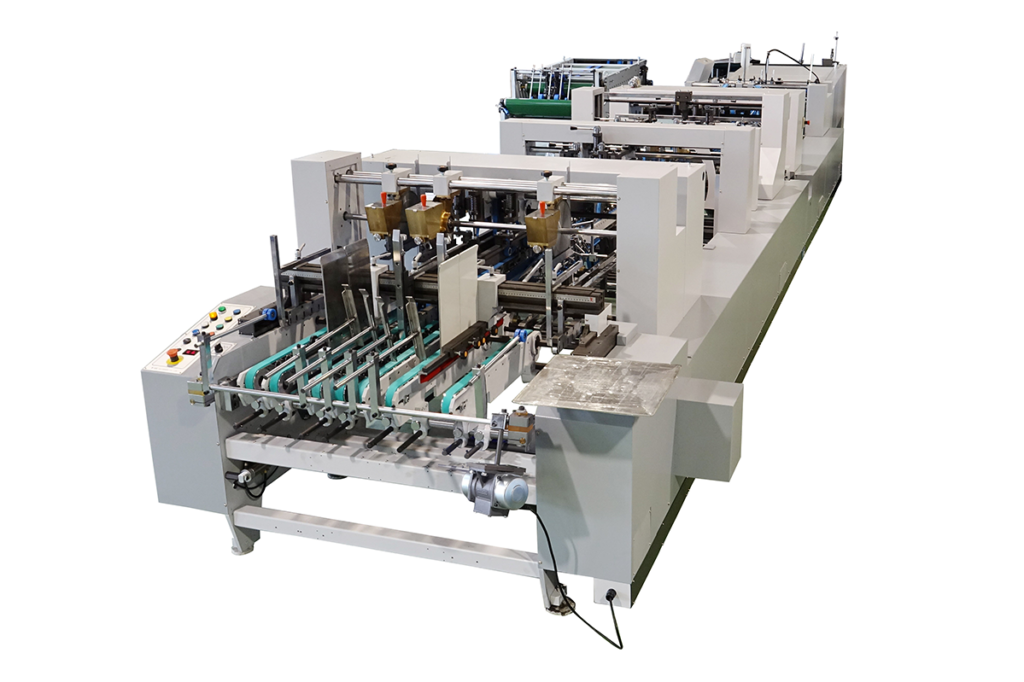

TS-1650WNV

High-Speed Folding and Gluing Machine

SPECIFICATIONS

| Stock Type | Carboard, E-flute corrugated and decorated board |

| Folding Capability | Standard folding boxes, double sides boxes, Crash-lock bottom boxes, 4/6 corners |

| Max. Speed | MAX. 200 m/min |

| Feeding | Automatic and continuous feeding |

| Pre-Folding | No.1 crease 180° , No.3 crease 135° |

| Glue Type | (For Glue Pot) Water based glue |

| Glue System | Consult glue system supplier |

| Power Required | 35KW, AC 220V |

| Machine Weight | 17000Kg |

FEATURES

1. Equipped with wireless remote control and screw rod that can be easily operated.

2. Max. machine speed of 200 m/min, power

transmission(transfer) unit adopt durable timing belt, low noise and easy to maintain.

3. Top belt drive system in pre-fold, bottom fold and final fold section. Can run either carton board or E flute corrugated board job more precisely.

4. Easy to operate upper gluing pot.

5. Specially equipped bottom gluing pot application for various box patterns.

6. Ability to do bottom and both sides gluing.

7. Pre-folding for No. 1 crease 180° and No.3 crease 135° speeds up production and easily connects to automatic packing device.

8. PLC program control system with two servo motor backing fold system, suitable for 4 &6 point boxes, cake, gift, lock bottom boxes, double wall boxes and standard straight line boxes production, Modulize options can be adapted to run each different appliance easily.

9. Heavy duty frame for various cardboard boxes, particularly E and B flute decorated corrugated board.

10. Upper compressor section uses sponge-like belts for smooth transfer to conveyor section where product is stacked.

11. Photo-electric counter for pre-set counting and batching.

12. A Standard machine include independent electrical cabinet, touch screen HMI.

13. A Large full color stacking monitor/CCD system allow operator to check upon shingled delivery from feeding section at all times.

14. EMS(-Stop) push buttons are located throughout the machine and on the remote control.

2. Max. machine speed of 200 m/min, power

transmission(transfer) unit adopt durable timing belt, low noise and easy to maintain.

3. Top belt drive system in pre-fold, bottom fold and final fold section. Can run either carton board or E flute corrugated board job more precisely.

4. Easy to operate upper gluing pot.

5. Specially equipped bottom gluing pot application for various box patterns.

6. Ability to do bottom and both sides gluing.

7. Pre-folding for No. 1 crease 180° and No.3 crease 135° speeds up production and easily connects to automatic packing device.

8. PLC program control system with two servo motor backing fold system, suitable for 4 &6 point boxes, cake, gift, lock bottom boxes, double wall boxes and standard straight line boxes production, Modulize options can be adapted to run each different appliance easily.

9. Heavy duty frame for various cardboard boxes, particularly E and B flute decorated corrugated board.

10. Upper compressor section uses sponge-like belts for smooth transfer to conveyor section where product is stacked.

11. Photo-electric counter for pre-set counting and batching.

12. A Standard machine include independent electrical cabinet, touch screen HMI.

13. A Large full color stacking monitor/CCD system allow operator to check upon shingled delivery from feeding section at all times.

14. EMS(-Stop) push buttons are located throughout the machine and on the remote control.