If you see printed material with a metallic imprint that looks like a mirror, you’re probably looking at the foiling printing technique. Foiling adds a “wow” effect to your printed items, catching the light in a way that other printing methods can’t.

Foiling is an excellent technique to set your printing apart from the competition by adding depth and almost crystal quality. Foiled spots gleam in the light, giving your printed pieces a high-end quality.

While a hot foil stamp machine is a traditional method, it is not always the ideal option. When deciding between traditional and digital hot stamping, the first thing to consider is the type of results you want to achieve.

SBL Machinery discusses the differences between traditional and digital foiling processes. This article will help you understand which is right for your project.

What is Traditional Hot Foiling?

When the term “foil stamping” is used in the industry, it usually refers to the process of hot foil stamping. This method involves using a metal plate with a raised impression of the design to be foil stamped onto the substrate’s surface.

When the plate comes into contact with the foil, a thin coating of the foil film is transferred to the paper’s surface. The foil adheres to the surface of the paper on the parts of the required imprint while the plate is heated. The image becomes reflective as a result.

Separate metal dies for each color must be prepared if multiple colors in a design need to be foiled. The dies are then applied one by one to the medium to create the desired result.

Pros

More professional results

Hot foiling provides finer detail when producing small or thin text. The stamping process slightly debosses the foiled elements, giving them a subtle shine when illuminated.

This method allows for completely custom holographic effects, such as having your logo show in the holographic ‘image.’ These customized holograms are typically employed as security devices. They also impart a unique and appealing feel to the printed work because they are difficult to reproduce.

More economical for longer print runs

While hot foil stamping is more costly for small and medium print quantities, it soon pays for itself if you’re creating large volumes of printed material.

Cons

Additional costs

You have to pay an extra fee for the foiling die assembly, which will vary depending on the size of the area you want to foil on your printed items.

Increased production times

Due to the time required to create the die block, setting up a hot foil job takes a lot longer. If you need to place an urgent order at the last minute, digital foiling is the way to go.

What is Digital Hot Foiling?

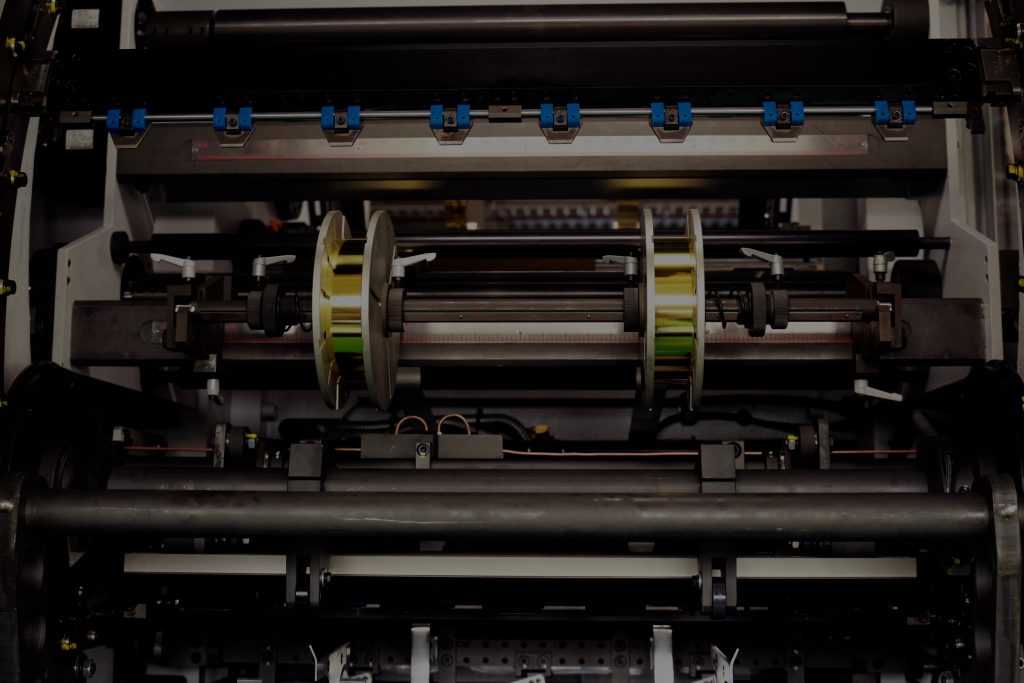

In terms of appearance, a digital hot foiling printing machine resembles a traditional one. However, the difference between them is in how the foil adheres to the medium’s surface.

The graphic design is digitally printed onto the medium using a specialized foil that adheres to the medium in the digital foil stamping. This method does not require the preparation of separate dies.

The process of digital foiling is very similar to that of traditional ink printing. If more than one color or design needs to be foiled, the machine does not need to be run multiple times.

Pros

Quicker production times

Digital printing can be done almost instantly. If you don’t have time to wait for a die block to be assembled, digital foiling is a great option for last-minute print runs.

Cost-effective for shorter print runs

Digital foiling is the more cost-effective option because there are no set-up costs and if you simply need to add foil in small to medium volumes of printing. You don’t have to spend extra on a hot foil die if you’re only going to use it for a few items.

Cons

Limited presentation quality

Though digital foiling looks impressive, it can’t replicate the aesthetic of hot foil stamping. Digital foil rests on the print’s surface rather than being debossed into the paper. Thus, it may not catch as much light or glint as a hot foil.

Requires lamination

A laminated surface is usually required if you want to get long-lasting results with digital foiling. Obviously, if you were planning on adding lamination anyway, this won’t be an issue – but if you want a more natural feel, you’ll have to choose between matte or soft-touch lamination.

Leading Provider of Hot Foil Stamper Machines

Whether you prefer to use a traditional or digital foil stamping machine, a high-quality hot foiling machine will help you complete your jobs more efficiently.

Clearly define your project goal as well as your budget from the start. If you have any questions, our customer service representatives can help you make the best decision.

SBL Machinery offers high-quality, safe, economical, and efficient equipment options that will improve your process. For inquiries, fill out our online form or call us at +886-2-2680-2199.

Related Posts

A sneak peek of 2024 DRUPA⼁From background history to current situation, exhibition products, and visitor results at once

Read MoreHot Stamping Machine Installation and Acceptance Guide: 3 Key Considerations for Buyers

Read MoreFolder Gluer Machine Installation and Acceptance Guide: 3 Key Considerations for Buyers

Read More