There are some mistakes done in using industrial die cutter machines especially by beginners. For instance, the die can fail to cut through the material completely. This kind of mistake can happen if the die lacks pressure behind it or if the material is too thick to cut through. For errors like this, you can run the material a second time through the machine or add a bulking material to increase the pressure.

Here are other usual die cutting mistakes and how to correct them:

Common Errors and Solutions in Die Cutting

Using a Wrong Pressure Sensitive Adhesive (PSA)

If the wrong adhesive is used, you can experience product failure. Ensure that you specify the PSA that your gasket converter will use on the next application. The solution to this is to choose the right adhesive by considering adhesion strength, life expectancy and temperature.

If a private label PSA is recommended, be sure it will work well for your application. Choosing cost-effective and high-quality options will ensure that you’ll have excellent results. Always keep in mind that the adhesive should stick to the mounting surface and seal. Cost, bonding limitations and sealing properties are important considerations when choosing the right sensitive adhesive for the job.

Only Choosing a Die Cut Gasket

A die cut gasket is not always the solution. It’s usually thrown away in some gasket manufacturing. To avoid this kind of waste, you can opt for a customized molded rubber gasket. If it’s a large application, you can use an extruded or spliced gasket. You can also have in-place gaskets to have fewer issues when dealing with thin gasket walls.

Not Having Specific Machining Tolerances

Manufacturing a die cut gasket is different from creating a metal part and it requires a wider tolerance. Tool type, features and production techniques are all important in die cutting techniques. You should understand the cutting process to equally match the gasket to have better processes.

Ignoring Test Cuts

Since materials can be expensive or scarcely available, cutter owners don’t usually do test cuts to save money and time. However, doing a test cut is encouraged so you’ll get an idea about different aspects of the material. You’ll get to know the blade sharpness, design and intricacy of the material and handle them better the next time you encounter these factors.

By doing a test cut, you’ll avoid wasting materials and you’ll thoroughly understand how much pressure to put on the tools. Being an expert in properly handling materials takes lots of trials, so initial testing is always important. It’s better to know the possible problems ahead of time than encounter them at the end which can be frustrating and time-consuming.

Failing to Determine the Reason for a Cutting Problem

You can encounter many issues while cutting your materials. However, if you know the factor that’s responsible for the problem, it will be easier for you to resolve it. For example, the force might be too low or the blade is not cutting the material properly.

If you see tearing, there might be an overexposure to the blade. To prevent further mistakes and to have a perfect cut, ensure the proper placement of your material to avoid redoing things all over again.

Improper Use of Blade Offset

Proper use of the blade offset is important especially when cutting rounded, hanging or bubbled corners. Take some time to know the settings of your machine to prepare for these kinds of materials. Not understanding it correctly can result in bad cutting techniques.

Not Stabilizing the Material for Cutting

Have a sturdy stabilizer for the material you’re cutting to prevent pieces from falling away and to give some backing to the material. You’ll get spots that are not properly cut if it’s not securely stabilized. Also, always check the thickness or adhesiveness of the material to have a cleaner cut in a single procedure.

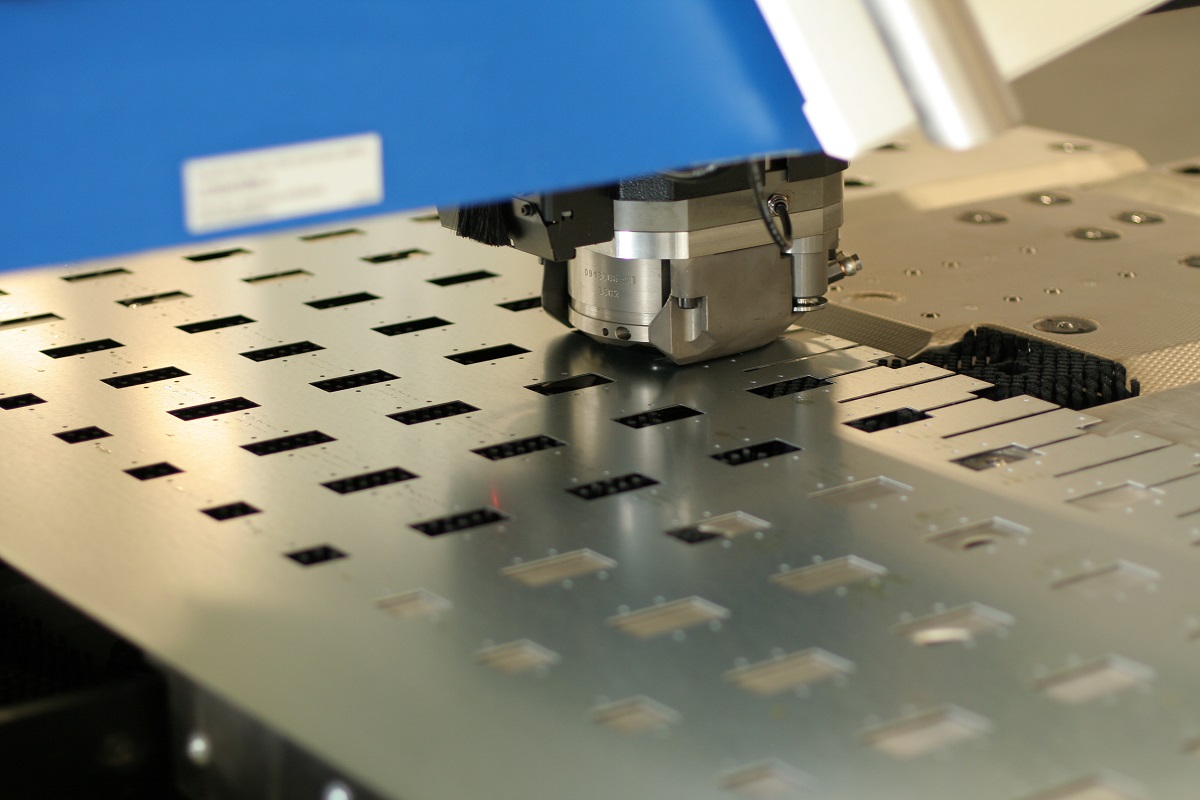

Reliable and Efficient Die Cutting Equipment

SBL is an award-winning provider of die cutting machines used worldwide. You’ll get high-quality products for mass production of packaging products and die-cut sheets. For reliable, safe and efficient equipment for your business, choose SBL machines.

For inquiries, call us today at +886-2-2680-2199 or fill out our online form.

Related Posts

A sneak peek of 2024 DRUPA⼁From background history to current situation, exhibition products, and visitor results at once

Read MoreHot Stamping Machine Installation and Acceptance Guide: 3 Key Considerations for Buyers

Read MoreFolder Gluer Machine Installation and Acceptance Guide: 3 Key Considerations for Buyers

Read More