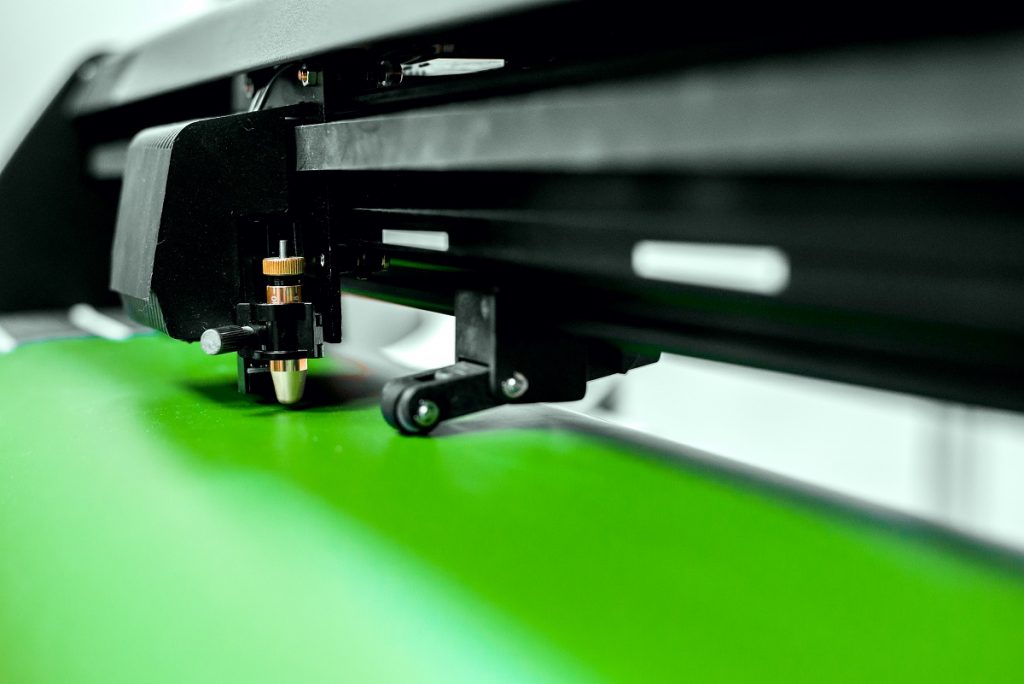

Die cutting is the process of drilling, cutting and shaping materials like paper, rubber, fiber or cardboard.

Industrial die cutters are mainly used in packaging businesses and are known to be very durable. Rotary die cutting is a quick and a cost-effective way of manufacturing products without compromising the speed of construction. It’s a good way to build items like boxes and other packaging materials.

Laser die cutting, on the other hand, involves the usage of high-speed lasers to cut materials. Lasers can be used to make various cuts and they don’t come in contact with the material. If your business needs a less expensive option, then a rotary die cutting machine will be perfect. A laser die cutter usually lasts longer but it’s a little pricier than the rotary die.

Here are some benefits of rotary and laser die cutting for your business:

Advantages of Rotary Die Cutting

-

Works well with difficult-to-cut materials

The rotary die easily cuts through any substrate almost at the same speed, unlike lasers that are usually dependent on the cut pattern. Rotary die cutting is also suitable for various materials like paper, foam, plastic and metal.

If your business is in graphic design or decorating, rotary die cutting machines are great for creating logos, book covers or wallpapers in different sizes. It’s also useful in the medical field, particularly for manufacturing adhesives for wound care.

-

Faster cutting speed

Rotary die cutting is faster than laser because the desired shape is already in the rotary die. Laser cutting has to adjust speed and depth depending on the cut. It’s also effective if you need to cut the same pattern on a bulk of sheets, regardless of the thickness.

-

Multipurpose

It can perform several tasks depending on your project’s needs such as embossing, laminating or kiss cutting – the cutting process done usually for stickers to prevent cutting all the way through the backing paper. It also creates less waste than other procedures, so it’s more economical and sustainable.

Advantages of Laser Die Cutting

-

Attention to detail

Laser die cutters are more accurate in cutting intricate designs like starburst patterns or cut outs. They have delicacy and extreme precision in cutting your labels no matter how challenging or unique the shape might be. Top-quality laser cutters can easily cut them while maintaining every detail. Its heat doesn’t cause distortion or warping on the material being cut. You don’t have to worry as the material won’t get excessively hot or deformed.

It can also be used in a huge variety of tasks like marking, drilling and engraving, and can also be used on plenty of materials such as plastic, stainless steel, wood or textiles.

-

Easy to maintain

It lasts longer than rotary die cutters and only needs a climate-controlled environment without too much humidity. This is to maintain the laser stability and it has interior components that are sensitive to heat. It may be more expensive than other options, but it will last a longer time as it doesn’t have a mold or knife that needs to be sharpened or replaced.

You also don’t need different molds for different kinds of designs. It doesn’t require too much maintenance, so it will save your company money.

-

User-friendly

With proper training, a laser die cutter is basically easy to operate compared to other blade-cutting options. It features a slim laser beam that won’t waste materials. This high-powered laser can be used on a narrow part of a material that can cause no distortion to the area. It can help you create complex geometries and cut your materials precisely.

-

Automated

Laser die cutters need little manpower as they’re highly automated. A well-trained machine operator plays a big role, but there’s a little need for manual labor that can result in lower costs compared to other methods. You can also opt for a machine with a feeding system and conveyors that will make your processes easier and accurate.

Wrap-up

While it may seem that there are more advantages to laser die cutting over rotary dies, the ultimate decision on which best suits you lie in other details. Clearly define your project goal and budget from the onset to help you make the right choice. If you’re unsure, our customer representatives are ready to provide any assistance you might need.

Leading Provider of Packaging Machinery

SBL offers a wide range of post-printing and packaging machines for your business. You’ll get high-quality, safe, economical and efficient equipment that will improve your processes.

For inquiries, call us today at +886-2-2680-2199 or fill out our online form.

Related Posts

A sneak peek of 2024 DRUPA⼁From background history to current situation, exhibition products, and visitor results at once

Read MoreHot Stamping Machine Installation and Acceptance Guide: 3 Key Considerations for Buyers

Read MoreFolder Gluer Machine Installation and Acceptance Guide: 3 Key Considerations for Buyers

Read More