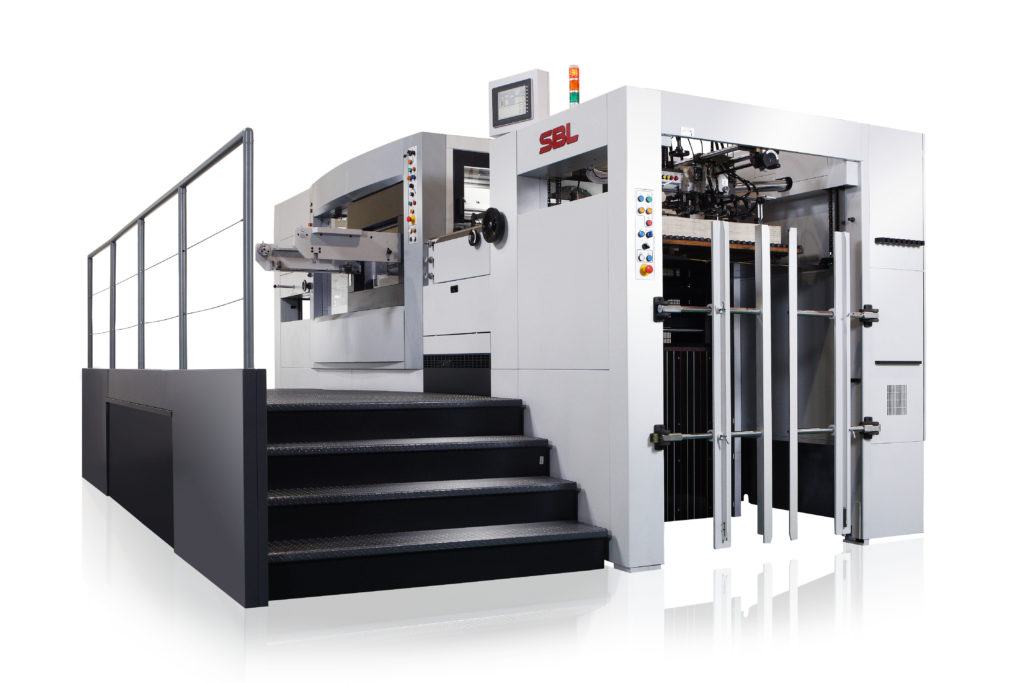

SBL-1300SE

Automated Platen Die Cutting and Creasing

| Max. paper size | 1300 x 950 mm |

| Min. paper size | 600 x 450 mm |

| Max. die-cutting paper size | 1290 x 940 mm |

| Min. gripper margin | 9.5mm |

| Die-cutting force | 500 Tons |

| Inner size of die chase | 1420 x 958 mm |

| Cutting plate size | 1328 x 940 mm |

| Range of material thickness | 0.1mm~2mm (80~1400gsm) |

| Corrugated paper | ≦4mm |

| Height of cutting rules | 23.6mm |

| Max. punching speed | 6000S/H |

| Register tolerance | ±0.075mm |

| Total power | 30KVA |

| Outer size of machine (mm) | 6769L × 2170W × 2244H |

| Machine weight (approx.) | 23 Tons |

| Feeder pile height with pallet | 1000mm |

| Feeder pile height with pallet (without non-stop) | 1000mm |

| Delivery pile height | 840mm |

| Feeder pile height with 350mm elevation (option) | 1550mm |

| Version | V.01 |

| Small sheet device (option) | – |

| Gripper bite (minimum) | 3mm |

1. The side guide adjustment ensures a perfect 90° angle between side guide and front lays at all times.

2. The slow down device on feed table allows sheet to enter head stop at a greatly reduced speed to ensure excellent register when running light weight stock.

3. Micro-adjustment device at delivery unit ensures safety.

4. Special push down device at delivery ensures proper stacking of large size sheets.

5. Pneumatic chase locking system to eliminate loose mechanical parts.

6. Recycling oil temperature controller to maintain an even cutting pressure.

7. Control system with computerized self-diagnostic monitor system provides information of each section to facilitate operation and troubleshooting.

8. LCD Digital display indicates the correct side guide adjustment required to keep side guide 90° to the front lay.

9. Wide range of stock from light paper to B-flute.

FEEDER

TOUCH SCREEN MONITOR SYSTEM

REGISTER DEVICE

SHEET SLOW DOWN DEVICE

PNEUMATIC CHASE LOCKING & AUTOMATIC IMPRESSION ON/OFF SYSTEM

DIE-CUTTING SECTION

STRIPPING DEVICE