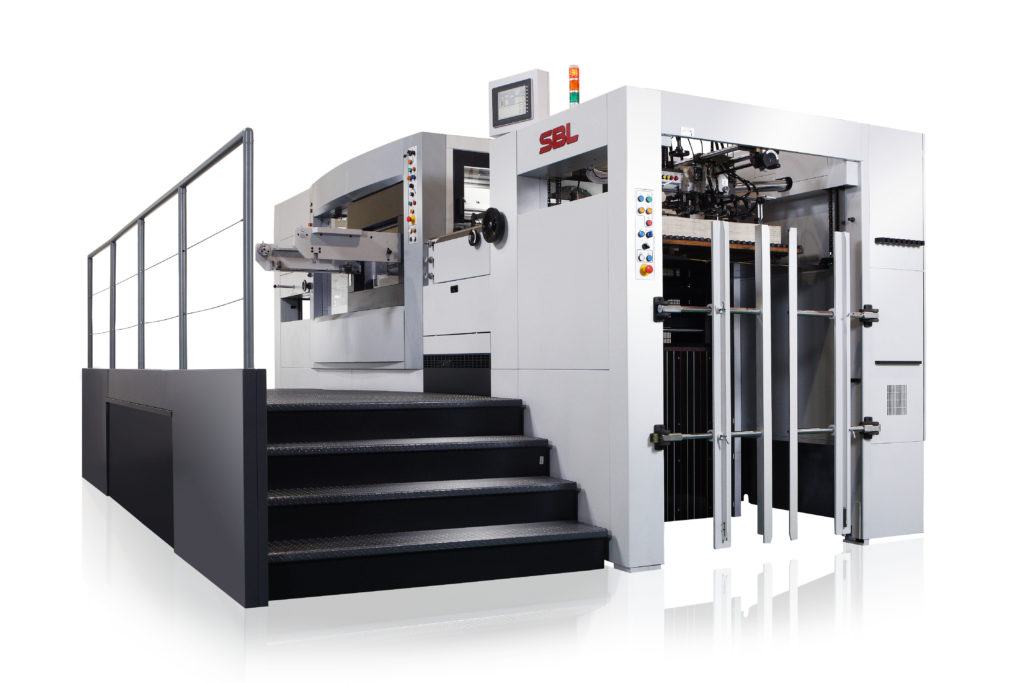

SBL-820E

Automatic Platen Die Cutting and Creasing

| Max. paper size | 815 x 605 mm |

| Min. paper size | 320 x 280 mm |

| Max. die-cutting paper size | 805 x 590 mm |

| Min. gripper margin | 9.5mm |

| Die-cutting force | 200 Tons |

| Inner size of die chase | 926 x 618 mm |

| Cutting plate size | 848 x 600 mm |

| Range of material thickness | 0.1mm~2mm (80~1400gsm) |

| Corrugated paper | ≦4mm |

| Height of cutting rules | 23.6mm |

| Max. punching speed | 8000S/H |

| Register tolerance | ±0.075mm |

| Total power | 15KVA |

| Outer size of machine(mm) | 4166L x 1869W x 1844H |

| Machine weight (approx.) | 9 Tons |

| Feeder pile height with pallet | 900mm |

| Feeder pile height with pallet (without non-stop) | 1000mm |

| Delivery pile height | 740mm |

| Feeder pile height with 300mm elevation (option) | 1300mm |

| Version | V.02 |

| Small sheet device (option) | – |

| Gripper bite (minimum) | 3mm |

1. Wide feeding range from 320x280mm to 815x605mm, maximum speed 8000 sheets/hour.

2. Non-stop device for feeder and delivery station can ensure continuing production.

3. The slow down device on feed table to ensure precise sheet feeding.

4. Double sheet and front lay register device can calibrate the sheet feeding.

5. Push and pull 2-in-1 side guide device to handle different stocks.

6. High strength alloy gripper bars.

7. Touch screen monitor with computerized self-diagnostic system is easy to operate and helpful for troubleshooting on each section.

8. Cutting pressure can be adjusted according to the stocks and the maximum pressure can up to 200 tons.

9. Various stock cutting range from light paper to B-flute.

10. The brush push down device and joggle device at delivery station to ensure proper stacking.

11. Highly safe and reliable machine.